Do you also want a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us.

New Control System for Jensen Senking Tunnel Washer with 18 Compartments

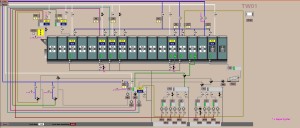

By order of Botved, leading supplier of equipment and systems for industrial laundries in Scandinavia, Senso Technics developed and installed a new control for the Jensen Senking tunnel washer with 18 compartments at Vraa dampvaskeri in Danmark.

The mechanical installation was still in excellent condition, but the control system required a modern, future-proof upgrade. With the new control solution, the tunnel washer is now more efficient, reliable, and optimized for sustainable operation.

Vraa Dampvaskeri is a large industrial laundry specialized in processing hospitality linen, towels, mops, company clothing, and mats.

“This tunnel washer is a very special one. There are only a few Jensen Senking tunnel washers wiht 18 compartments still operating worldwide, says our PLC Software Engineer at Senso Technics.

Developing a new control system for this Senking tunnel was therefore a unique and challenging project. The strength of this installation lies in its versatility and advanced water reuse concept.

In addition to using filtered water through the AquaCycler of Ecolab, Vraa Dampvaskeri stores filtered rinse water in large buffer vessels for reuse later in the washing process. This setup significantly reduces water and energy consumption.

To support this sustainable approach, Senso Technics developed several smart control features, ensuring optimal management of water flows, buffers, and process timing. maximizing efficiency without compromising wash quality.

Founded in 1956, Vraa Dampvaskeri is not only one of Denmark’s largest industrial laundries, but also one of the most innovative.

The company serves thousands of employees across industries such as:

Vraa Dampvaskeri specializes in the rental and cleaning of:

Workwear

Hotel and hospitality linen

Towels, table linen, and napkins

Mops and mats

Through continuous investment in sustainable technology and process optimization, Vraa Dampvaskeri

remains at the forefront of efficient and environmentally conscious laundry operations.

This project demonstrates how existing tunnel washers can be upgraded with modern control systems, extending machine lifetime while significantly improving efficiency and sustainability.

A strong example of how smart software and proven mechanics come together in a future-ready industrial laundry solution.

Do you also want a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us.