Do you also want a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us.

Kannegiesser dryers and Senso Technics control make a powerful combination when it comes to optimizing processes in modern industrial laundries. At Elis Laundry Services, a series of brand-new Kannegiesser dryers have recently been installed. These machines are seamlessly integrated into the existing Senso Technics control system, expanding the functionality of a centralized automation setup.

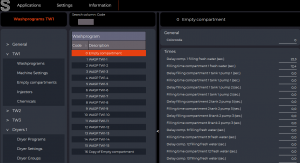

Thanks to the smart integration with Senso Control, Elis now benefits from a fully centralized control system. All major components of the laundry – including the sorting station, soil-side monorail system, tunnel washer, press, shuttle, and now the Kannegiesser dryers – are monitored and managed from a single workstation.

This approach offers several advantages:

Clear real-time insights into all production stages

Fewer operator interventions

Better synchronization between machines

Improved efficiency and traceability

The laundry process at Elis starts when soiled linen enters the facility. Each customer and article is identified and registered automatically. Above the sorting station, a display shows the customer name, article type, and current bag weight.

Once the pre-set weight is reached, the sorting bag is released and transported via the soil-side monorail system to the appropriate storage line. Later, using a call-off via the Senso Suite software, the requested batch is sent to the tunnel washer, which also runs on Senso Technics control.

This integrated approach allows for one uniform control system across multiple machines and laundry zones, streamlining communication, reducing errors, and improving response times.

Although the new Kannegiesser dryers come with stand-alone controls, Elis Laundry Services opted to integrate them into the existing Senso Technics automation platform.

To achieve this, digital input and output signals are exchanged between the dryers and the Senso system. This enables centralized control commands and feedback loops, such as:

Start and stop commands

Program selection

Monitoring dryer status

Receiving error messages

This connection gives the operators full control and visibility from the central workstation, even though the machines technically remain stand-alone.

The cooperation between Kannegiesser equipment and Senso Technics software demonstrates how different technologies can work together to create a future-proof and efficient laundry.

By integrating these systems, Elis not only optimizes daily operations but also ensures scalability and flexibility for future growth and process expansion.

Do you also want a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us.