Do you also want a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us.

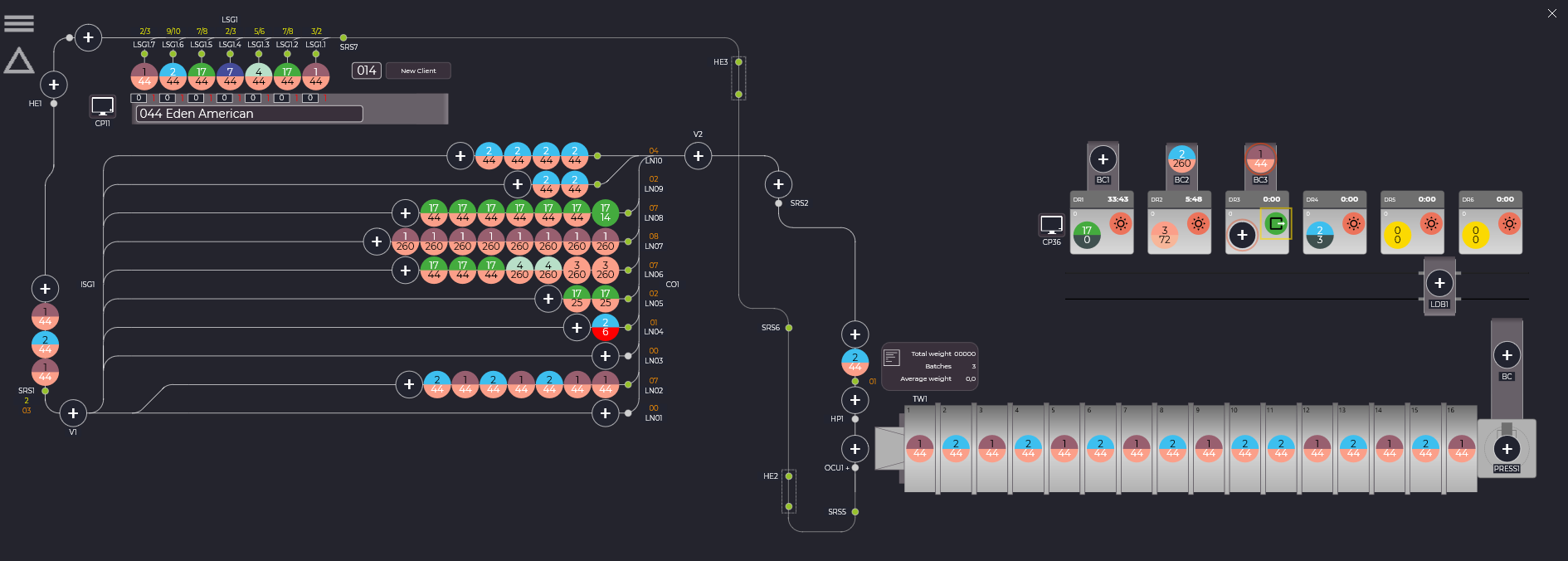

Laundry software SensoSuite offers one control system for industrial laundries. The moment the soil linen enters the laundry customer and article are registered on a Senso Technics workstation. The soil linen batch receives an unique track and trace number. So you know where your customer and the articles are within the laundry process.

Which laundry sorting system suits a laundry often depends on the quantity of article and volume. Which choice you made or make, laundry software helps you with sorting hoists, sorting belts, sorting group with lift rail system, sorting bins, and bags. With laundry software, by entering the articles, you can optimally set the washing and drying process. While sorting weight, customer, articles and storage line destination are displayed, if you want to (temporarily) storage the sorted linen.

By setting the call-off in SensoSuite laundry software automatically, you can always have your tunnel washer function optimally. One article, as you know, needs more washing and drying time than another. If you want to change it manually, then of course that is also possible. When you use a soil side monorail and buffer lines, the automatic call-off is certainly the solution for you. This allows the “oldest” bags to go out first, when the tunnel washer is available again.

SensoSuite Laundry software offers you also the control for the tunnel washer. When you use the existing control of your tunnel washer, you can add the software to your laundry to control the call-off of the soil linen. Customer, article and wash program are communicated to the existing tunnel washer control.

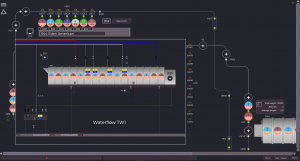

When you use the laundry software to replace your current control system, you control the tunnel washer with SensoSuite. With a clear water flow, pumps and valves are controlled and the right washing and dosing program is given, adjusted to your chemical plan. The linen continues its way through the tunnel by moving from compartment to compartment. You can easily see where the customer and article are located with the user-friendly laundry software.

When the press needs a new control you can replace it with SensoSuite laundry software control. The press receives a signal from the tunnel washer. In this way the press knows that the correct press programme is activated. When the discharge conveyor or shuttle is ready for use, the clean linen batch moves to the next position in the laundry process.

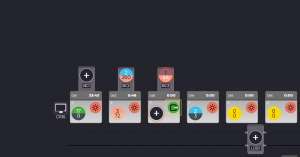

For existing dryers the current control can be replaced by a new control. The new dryer control communicates with the dryers so the correct drying program is offered to the linen being dried. The dryer is loaded with the desired wash batch (customer, article). After drying, the dryer unloads the linen or terry onto a discharge conveyor, into a linen cart or into a clean side monorail D3. The new dryer control comes in handy, when the current control is no longer functioning properly or spare parts are not available again and your dryers are still working properly. Or when you want to expand your existing dryer group. Regardless of the year of manufacture or production.

For existing dryers the current control can be replaced by a new control. The new dryer control communicates with the dryers so the correct drying program is offered to the linen being dried. The dryer is loaded with the desired wash batch (customer, article). After drying, the dryer unloads the linen or terry onto a discharge conveyor, into a linen cart or into a clean side monorail D3. The new dryer control comes in handy, when the current control is no longer functioning properly or spare parts are not available again and your dryers are still working properly. Or when you want to expand your existing dryer group. Regardless of the year of manufacture or production.

SensoSuite monitors the active production hours and numbers of your machines and employees. The employee logs in at the terry folding machine or irioner with a keycard or tag. Name of the employee and article are visible on the monitor above the folding machine or irioner. The standard norm per hour can be entered per article. So you and your employee know if the production goals can still be achieved.

Would you like to have insight into your laundry processes at any time? Serve your customers and at the same time manage your textile laundry as efficiently as possible? Do you want to be sure that all the laundry is sorted correctly? Or be able to flexibly shift your customer assignments? Senso Technics’ laundry management software SensoSuite fulfils these wishes for you both as a total solution and as part of the laundry process and machine.

Are you also interested in a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us mail to sales@sensotechnics.nl or call +31 88 4262300

Do you also want a smart solution for your industrial laundry? Are you curious whether you can perform better in terms of performance, production and happier customers? Please do not hesitate to contact us.